.jpeg)

iBraze

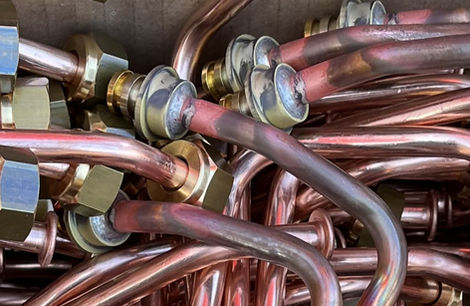

Brazing is a type of welding that joins two metal pieces, even of different materials, without affecting the structure of the pieces.

The process takes place by heating the two pieces to be joined without melting them, once the optimal temperature is reached, a filler material (alloy) is inserted which melts at a lower temperature and joins them together. The junction takes place via capillarity. The strength of capillarity is represented by the ability of the molten alloy to penetrate all the cavities of the pieces to be joined, filling them. Once cooled, it solidifies and joins the parts without leaving holes or porosity.

Brazing has considerable advantages:

-

join dissimilar materials

-

integrity of the pieces to be welded

-

resistance over time

-

does not require other treatments or finishing processes on the pieces

This technique is commonly used for the production of compressors for household appliances, radiators, heaters and heat exchangers.

Temperature Too Low

Solder does not flow

Correct Temperature

Solder flows and bonds

Temperature Too High

Solder becomes brittle/burns

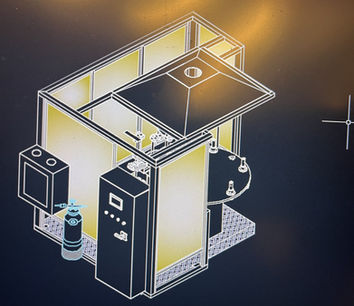

TECHNICAL CHARACTERISTICS iBraze 4.0

Overall Dimensions

Total weight of the machine

Productivity

Pneumatic system

Technical gas system

Oxygen system

Sound level

220 x 243 x H 200 cm

1.500 kg

Up to 4000 pz / day

Tubo rilsan Ø 10 / Max 8.0 bar

Tubo 15x8mm / Max 1,0 bar

Tubo 15x8mm / Max 6,0 bar

65 DB (A)